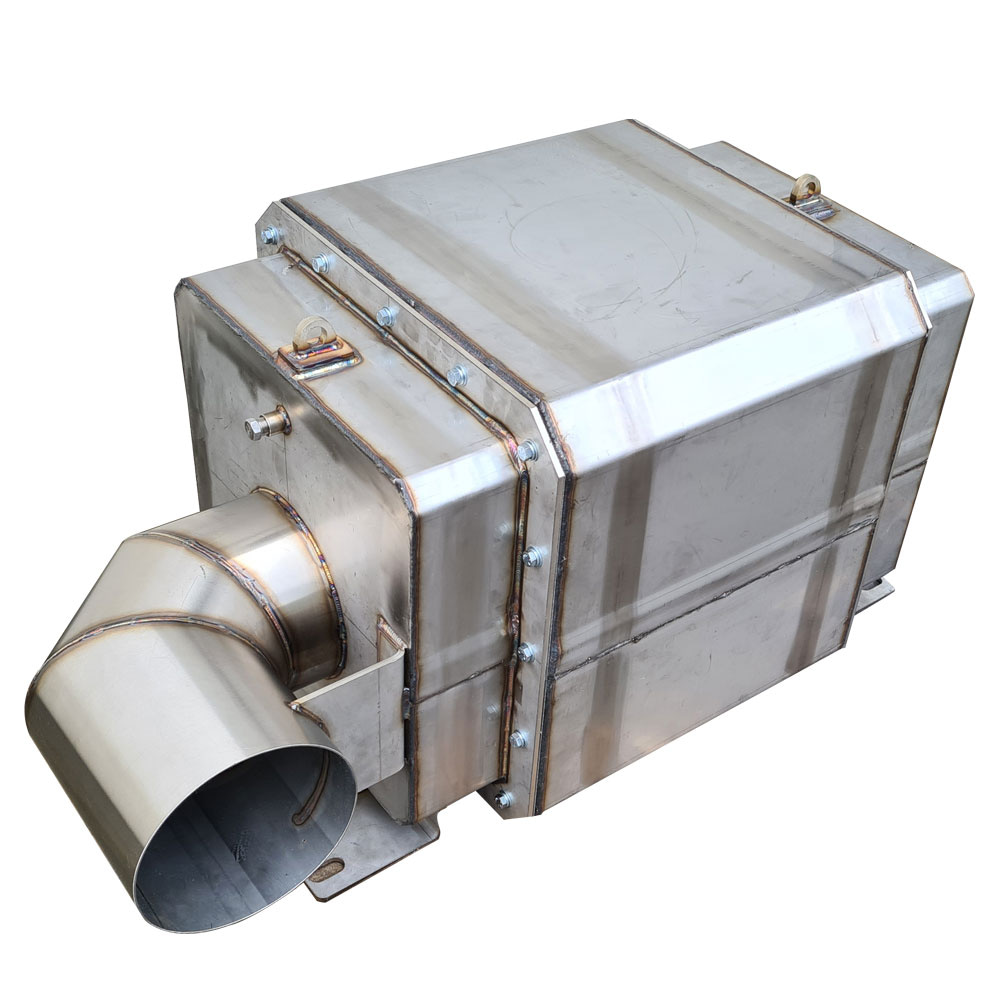

- DPF + Pre-Catalyst

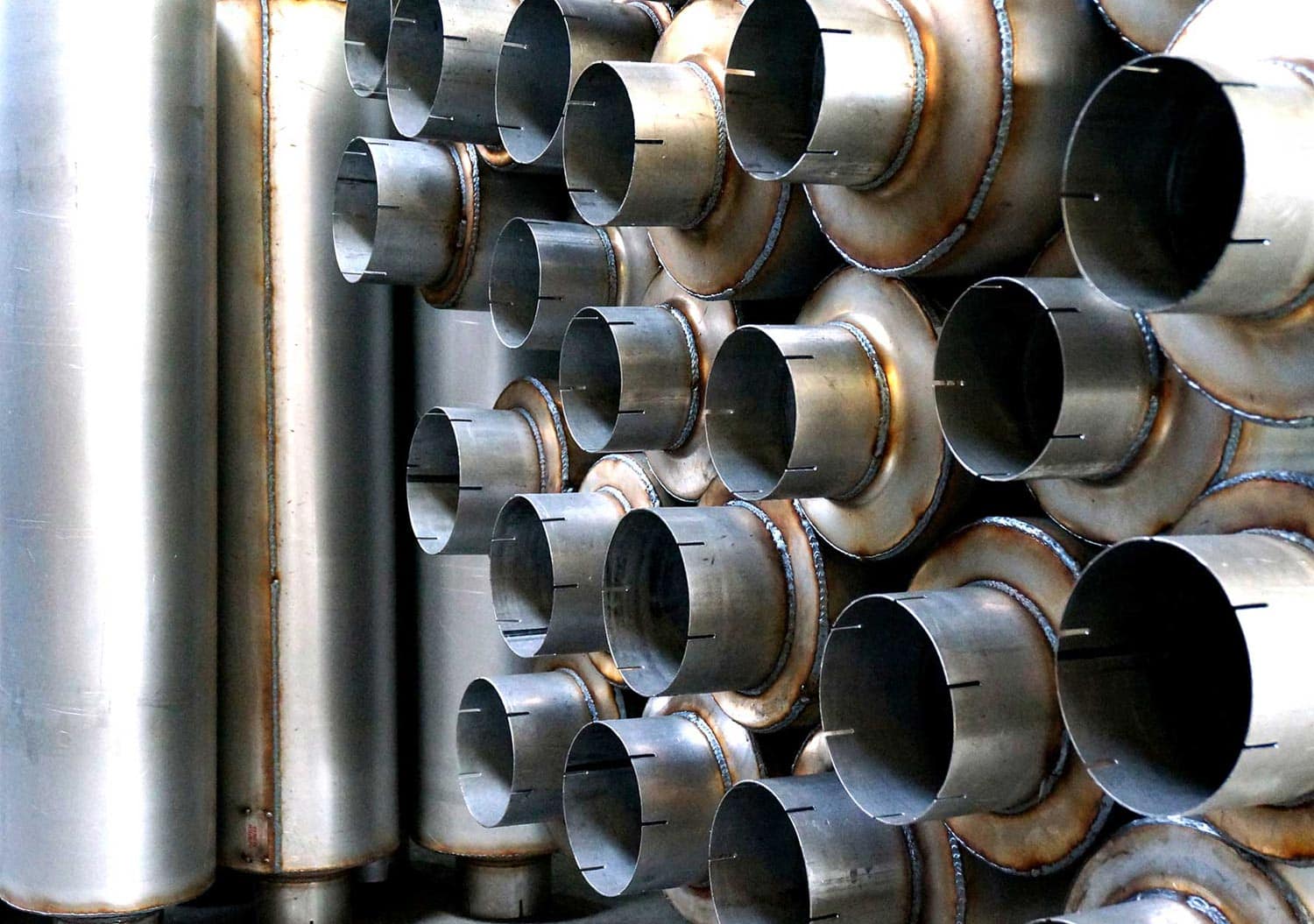

- DPF - Ceramic

- Catalyst Combo Filter

- DOC

| Particulates | DPF + Pre-Catalyst | DPF - Ceramic | Catalyst Combo Filter | DOC |

| Particulates | $3999 /year | $3999 /year | $3999 /year | $3999 /year |

| Carbon Monoxide (CO) | 98 | 90% | 96% | 90% |

| Hydrocarbons (HC) | 82 | 80% | 88% | 80% |

| Nitrous Oxide (NOx) | - | - | - | - |

| Particulate Matter (PM) | 98 | 95% | 75% | 25% | Learn More | Learn More | Learn More | Learn More | Learn More |