Frequently Asked Questions

Here are some of the most frequently asked questions about Flowtech exhaust wraps.

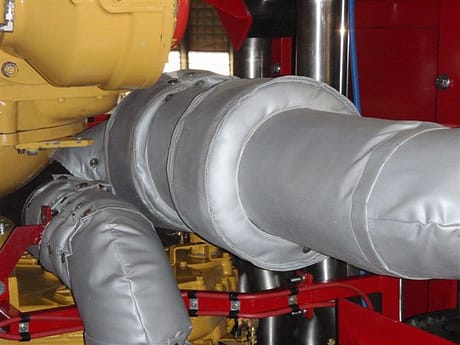

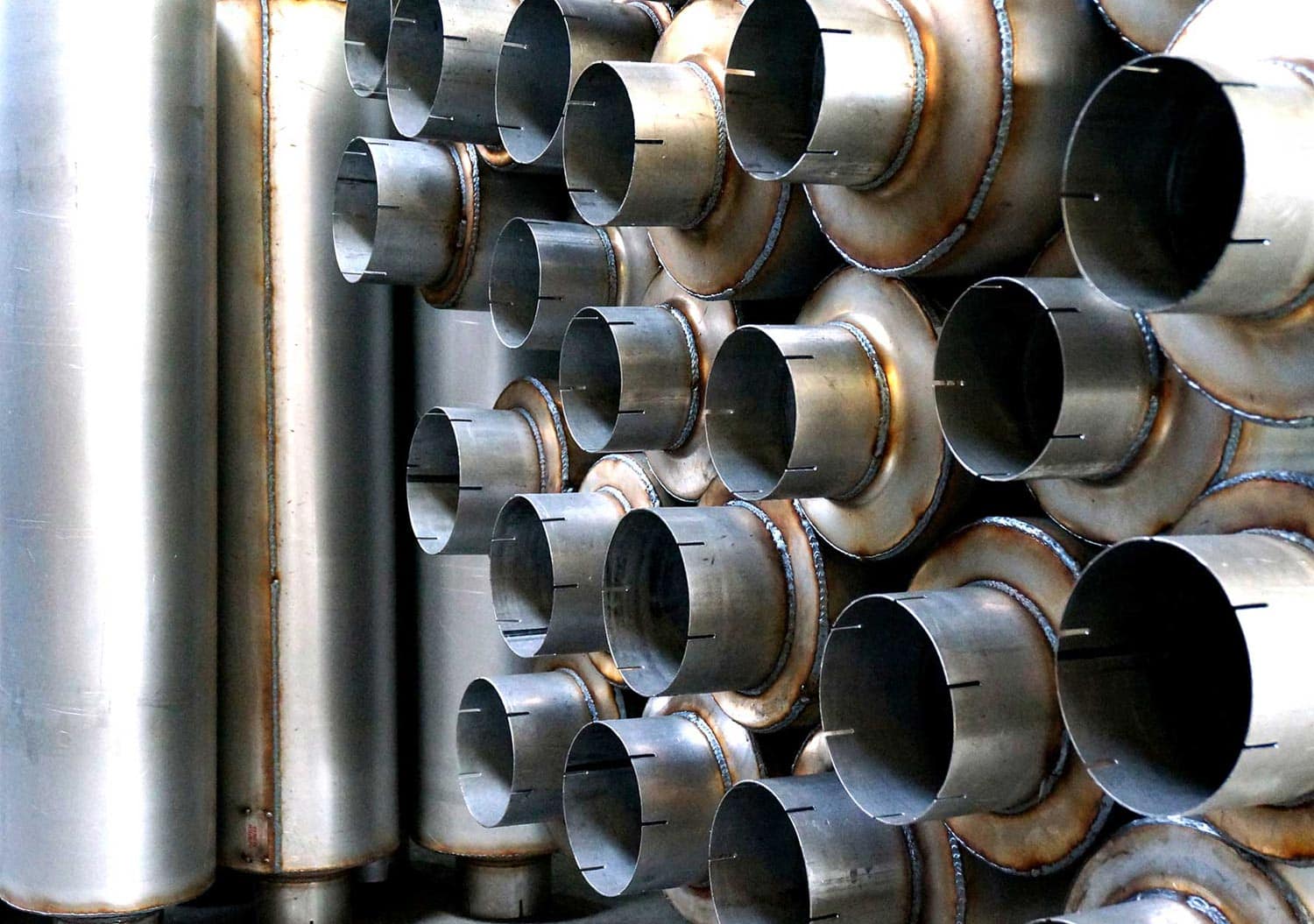

Exhaust heat wrap is a heat-resistant material primarily used in automotive exhaust systems, although it can also be applied to exhaust pipes, heavy-duty engines, generators, and manifold systems. Its purpose is to minimize thermal stress on the components and enhance engine performance.

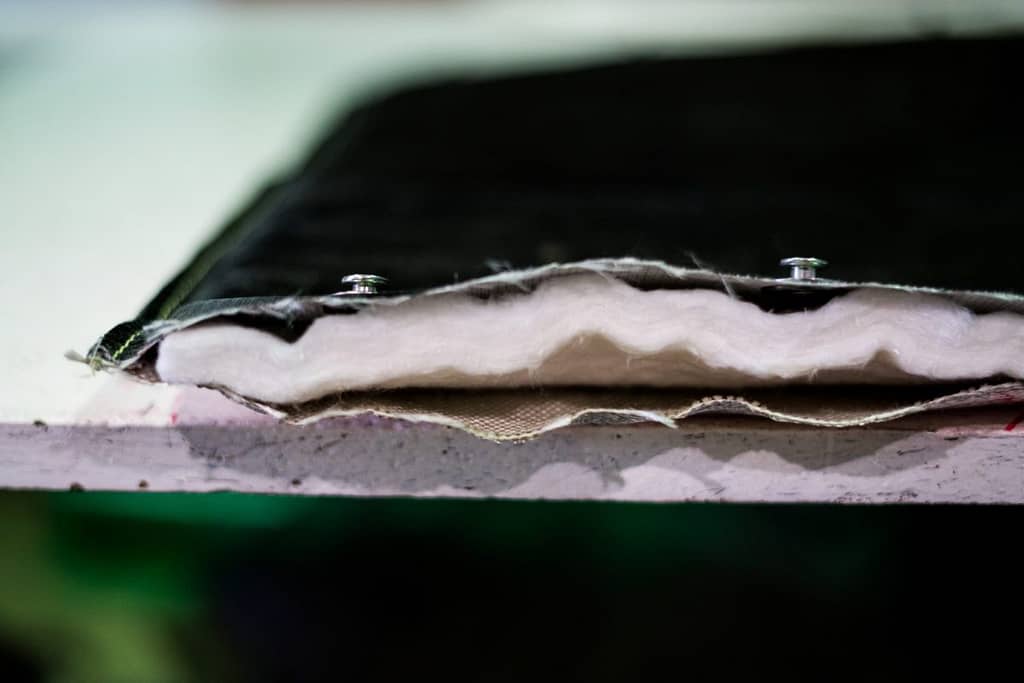

By reducing heat transfer and maintaining optimal operating temperatures, exhaust wrap plays a crucial role in improving the longevity and efficiency of these systems. It can be made from ceramic fibre, glass fibre, or even aluminium-coated silica glass.

The duration of lagging in the exhaust or engine depends on various factors, such as the environment and the average temperature in which the machine operates. Additionally, the usage and type of heat wrap used should be taken into consideration. It’s important to note that oil or any liquid leaks from the engine can potentially damage the lagging.

However, with proper maintenance, exhaust wraps typically have an average lifespan of 3-5 years.

- Improved engine performance

- Better fuel economy

- Increased longevity of components and systems

- Enhanced exhaust flow rate

- Minimized thermal stress on the parts

- Reduces underhood temperatures to improve air intake efficiency.

When installing exhaust wrap, it’s important to keep a few things in mind:

- Always clean the surface before applying the wrap.

- Make sure to leave some space between the engine and the wrap in order to allow for optimal airflow

- Use a temperature-resistant adhesive in order to ensure that the wrap stays in place

- It is important to inspect and maintain your exhaust wraps regularly, as they can degrade over time due to heat.

- The use of the studs method is the preferred method as it’s attached to the outer layer of the insulation

- Stitching is essential for holding all vital layers together. Ove stitching should be avoided.

It is highly recommended to hire a professional installer to ensure a thorough and precise installation. This ensures that shortcuts are avoided and proper tools are used to achieve the best results.