DPF + Pre-Catalyst

This Diesel Particulate Filter with Pre-Catalyst is a specialist combination designed to remove High levels of Carbon Monoxide (CO), Hydrocarbons (HC), and high levels of

Diesel engines have become essential in various manufacturing, industrial, mining and transportation industries. However, they produce harmful gases such as carbon monoxide (CO), hydrocarbons(HC), and Diesel Particulate Matter(DPM) that pose significant health risks to the personnel especially in a confined workspace area.

The Australian government has set strict standards to regulate these emissions to protect the public and reduce environmental impact.

Related article: Heavy vehicle emission standards for cleaner air

The Euro 4 standard is a set of regulations that aim to reduce emissions produced by new vehicles and machinery. The European Union implemented these standards in January 2005, and several countries have since adopted them.

Related article: Emission 4 Engine

The standards require significantly reducing carbon monoxide, hydrocarbons, and nitrogen oxide emissions. Additionally, these regulations require a reduction in diesel particulate matter by 75%. Compliance with Euro 4 standards ensures that diesel engines are environmentally friendly.

To meet these high standards, numerous industries are increasingly adopting the installation of a DPF. This helps them comply with regulations, improve engine performance, and minimize engine maintenance requirements.

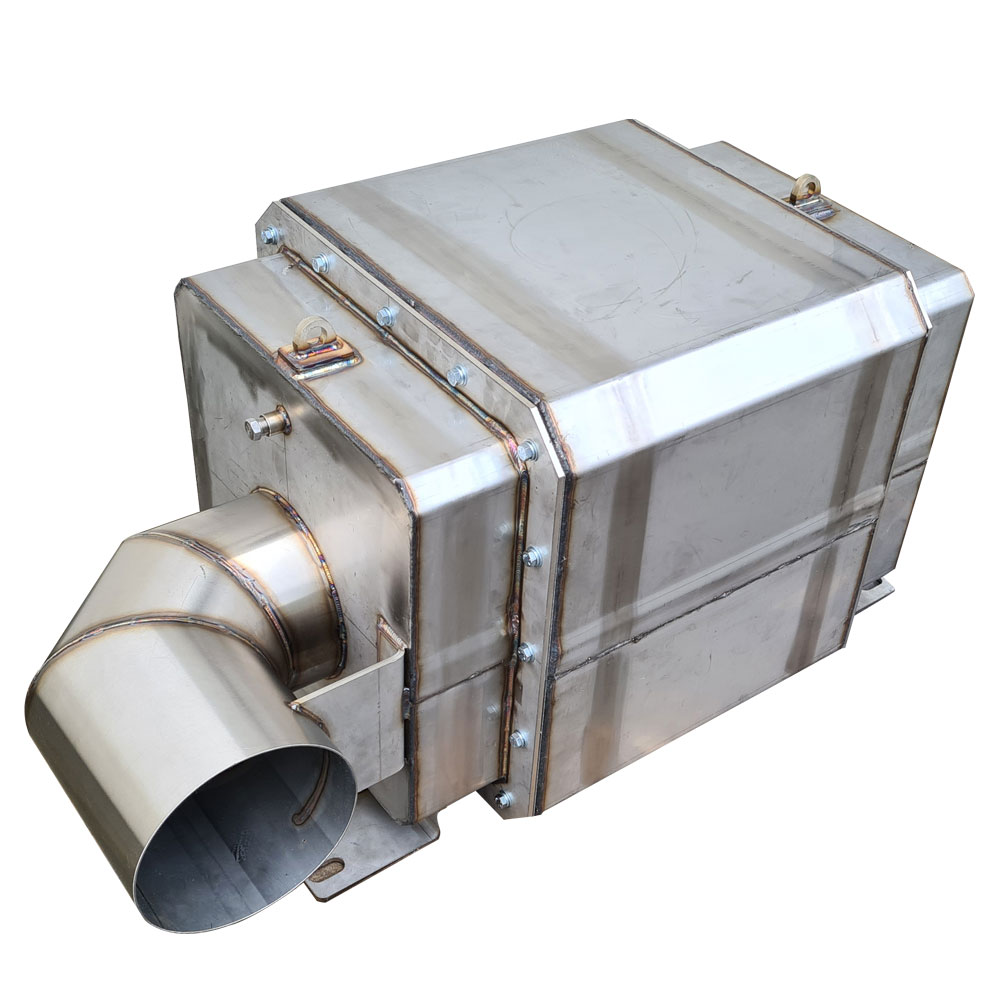

Our client in New South Wales, offering engineering services to the mining, industrial, and construction sectors, required a Diesel Particulate Filter (DPF) for a larger 3.8L engine operating at 1800rpm.

The Flowtech team recommended installing a custom DPF that meets Euro 4 standards and can function as a Filter and a Silencer in one.

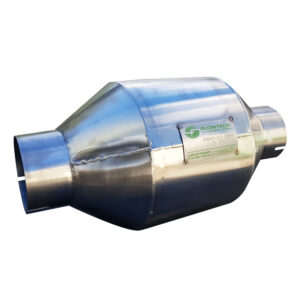

In addition, an extra catalytic converter was added to the engine system to further reduce emissions. As a result, our client achieved cleaner emissions making their workplace safer.

The Flowtech custom DPF design is a combination of Diesel Oxidation Catalyst also known as (DOC) and Particle Oxidation Catalyst (POC) proven in removing a high level of Carbon Monoxide (CO), Hydrocarbons (HC) as well as over 60%-75% of Diesel Particulate Matter (DPM)

Reduce fuel efficiency – The build up of diesel particulate matter can also cause irreversible damage to engines and lead to expensive maintenance costs. A custom DPF filter will prevent issues and reduce your maintenance expenses in the long run.

In conclusion, custom DPFs are essential in reducing the harmful emissions produced by diesel-powered machinery and meeting stringent emission standards.

The Flowtech team offers customised solutions that guarantee compliance with Euro 4, 5 and 6 standards while improving overall performance and reducing maintenance costs.

Investing in a Flowtech custom DPF Muffler will go a long way in protecting the environment, the public’s health, and your industrial machinery.

Contact us to learn more about our custom DPF and how it can achieve Euro Emission standard requirements.

This Diesel Particulate Filter with Pre-Catalyst is a specialist combination designed to remove High levels of Carbon Monoxide (CO), Hydrocarbons (HC), and high levels of

Ceramic Diesel Particulate Filters are designed to remove High levels of Carbon Monoxide (CO), Hydrocarbons (HC), and High levels of Particulate Matter (PM) from Diesel

The Flowtech Diesel Oxidation Catalysts, or DOCs, can be a lifesaver when it comes to reducing emissions from diesel engines and equipment. Whether you’re driving

We have a wide range of muffler solutions for every industry.

Explore our Spark Arrestors, Exhaust Silencers, Emission Control, Aftemarket Exhaust Parts and Performance Muffler

Our client operates within the sand mining sector, heavily relying on CAT generators for their daily functions. The objective was to replace deteriorating mufflers with Flowtech Silencers to curb emissions and reduce noise pollution. This improvement was crucial for adhering to updated environmental standards and enhancing the workplace atmosphere.

Our client operates within the sand mining sector, heavily relying on CAT generators for their daily functions. The objective was to replace deteriorating mufflers with Flowtech Silencers to curb emissions and reduce noise pollution. This improvement was crucial for adhering to updated environmental standards and enhancing the workplace atmosphere.

Our client operates within the sand mining sector, heavily relying on CAT generators for their daily functions. The objective was to replace deteriorating mufflers with Flowtech Silencers to curb emissions and reduce noise pollution. This improvement was crucial for adhering to updated environmental standards and enhancing the workplace atmosphere.

When it comes to heavy machinery, the performance of components like DPF filters can significantly impact overall efficiency and longevity. This case study will delve into how the Flowtech Diesel High-Flow Combination Filter, specifically designed for the CAT 120M Motor Grader, has shown to be a game-changer in terms of improving emission output from harmless pollutants to cleaner releases.

Our client in Sydney needed a new muffler for their 2250KVA Cummins Diesel Generator. The old muffler had rusted and lost its effectiveness, so they approached the Flowtech team for help.

Our task was to design a modern silencer that would not only reduce noise but also resist corrosion and last longer.

Once again, our loyal client in Western Sydney has entrusted the Flowtech team. The team designed a unique muffler that serves as a filter and a silencer effectively minimizes the emission of harmful fumes and reduces noise levels.

Here are the top three reasons why we’re their preferred solution provider

Homegrown and proud, Innovating solutions for three generations, providing a wide range of customised exhaust systems that are robust, reliable and cost effective to meet the diverse demands of our clients.

What sets us apart is our unique custom exhaust and emission control solutions with quick turnaround times that we can distribute throughout Australia & New Zealand.

We understand that when you place an order, you want it expedited as quickly as possible. That's why we offer same-day dispatch on all standard items. Your order will be processed and shipped out within 24-hours.

Top mining, automotive and multiple industries trusted our service for more than three decades. We Specialised in designing and manufacturing high-quality exhaust products that meet the unique needs of our clients.

Let us assist you in finding a reliable exhaust solution tailored to your needs.

Since 1984, Flowtech Advantage has been a key manufacturing division of CSC Group Australia. With its main headquarters in Western Sydney, the company designs and produces exhaust solution components for most industries in Australia and New Zealand.

Flowtech Advantage Australia

13 Windsor Street Richmond NSW 2753

t. 1300 885 089

e. [email protected]

Fill in your details and we’ll send you regular updates about Flowtech Advantage products.