Cummins Diesel Generator Muffler

Diesel Generator excessive noise issue

The problem of noise pollution is becoming a growing concern, particularly for companies that operate in close proximity to residential areas that utilize heavy-duty equipment. Various industries such as construction, mining, and agriculture are actively pursuing solutions to minimize the noise generated by their equipment and machinery.

Our client, a Victoria-based company in Australia specializing in diesel generator and engine solutions faces a similar issue and now requires a customised muffler for their 110kVA Cummins Diesel Generator. The objective was to meet certain noise level reduction (35-40 dBA) requirements while enhancing safety by reducing the emission of hot particulates from engine and exhaust systems.

Diesel generators are extensively used across industries as a dependable power source. However, they have gained notoriety for producing excessive noise levels. This issue can also lead to work delays due to restricted working hours caused by noise disturbance.

Design, plan & achieve quiet efficiency

The Flowtech team was approached to develop a solution for noise and spark-related issues.

Solution #1: Design and customise SILENCERS to suit the Cummins Generator and achieve a specific noise level reduction.

Solution #2: Adding a SPARK ARRESTOR to ensure compliance with AS1019-2000 standards.

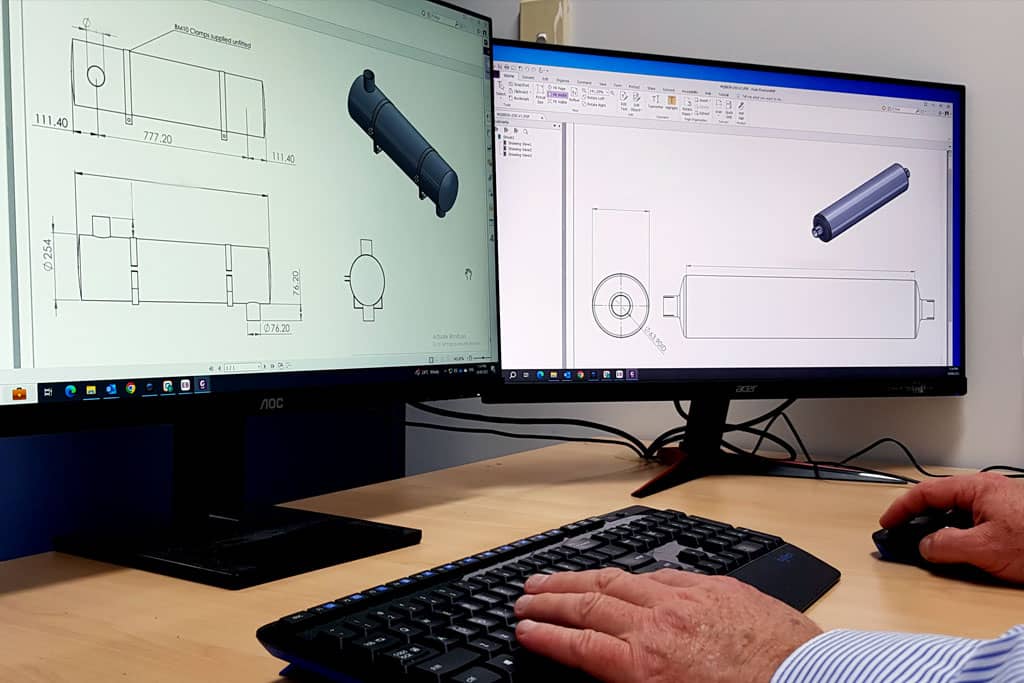

The initial step involved gathering the precise requirements from the client and carefully analyzing the materials provided to our team.

To ensure accuracy, CAD drawings were drafted to confirm all measurements and details.

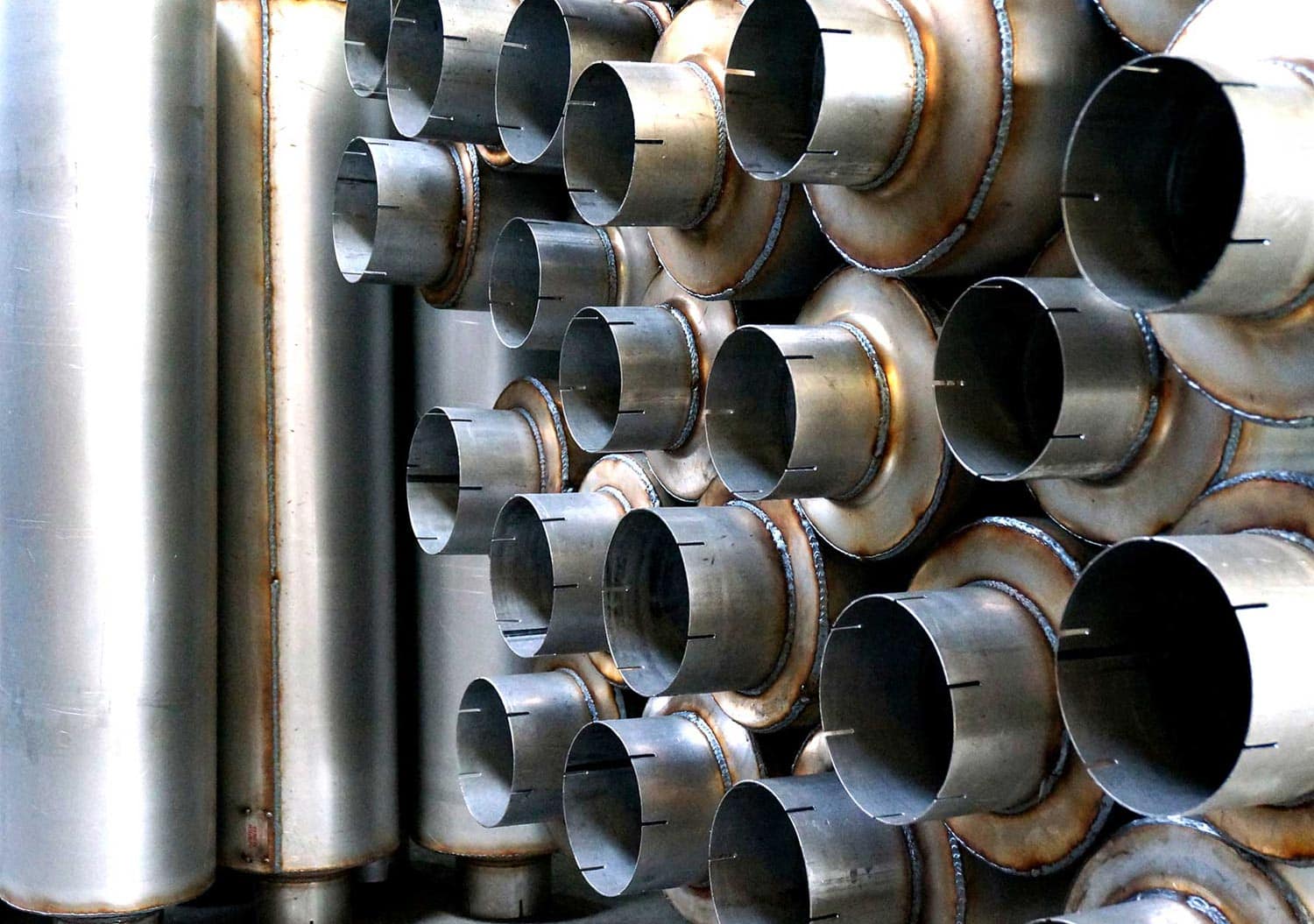

Once we got the approval from the client, we then proceeded to manufacture the components required to construct the silencers suited for Cummins Generator.

The ultimate custom muffler solution

After spending several days working on design and prototype testing, we finalized the product with a set of tailor-made Flowtech Silencers. These silencers were meticulously designed and constructed to meet the client’s specific requirements. We managed to achieve an impressive noise reduction level of 35-40 dBA range. On top of that, we also built a Flowtech Spark Arrestor that adheres to Australian standards.

The Flowtech Spark arrestors prevent sparks or other combustible materials from escaping the exhaust and potentially causing fires or explosions. This is especially crucial in diesel generators that operate in hazardous environments, such as mines, oil rigs, or chemical plants, where a stray spark can cause catastrophic damage.

Spark arrestors usually have a metal screen or mesh that traps sparks without obstructing the exhaust flow. Many jurisdictions, including Australia, mandate spark arrestors in diesel generators that operate near flammable or explosive materials.

Source: Australian Standards AS 1019-2000

Custom Muffler Project Success

Our client expressed overall satisfaction with the final outcome. The tailored Silencer muffler not only met the noise level criteria but also ensured the safety of their equipment and operations by adding a Spark arrestor. In addition, the design was able to fit perfectly within their existing Cummins generator.

We’re proud to have been selected as their supplier of choice for this project and look forward to working with them in the future.

Related Products

Looking for a similar solution?

We have a wide range of muffler solutions for every industry.

Explore our Spark Arrestors, Exhaust Silencers, Emission Control, Aftemarket Exhaust Parts and Performance Muffler

This project is related to Generator Muffler Silencer

Discover More Case Studies

Our exhaust solutions are custom tailored to suit your specific needs.

Silencers

DPF Filter for CAT 120M & 140M Grader

When it comes to heavy machinery, the performance of components like DPF filters can significantly impact overall efficiency and longevity. This case study will delve into how the Flowtech Diesel High-Flow Combination Filter, specifically designed for the CAT 120M Motor Grader, has shown to be a game-changer in terms of improving emission output from harmless pollutants to cleaner releases.

February 26, 2024

No Comments

Silencers

Silencer designed for CAT 3412 Diesel Generator

Our client in Sydney needed a new muffler for their 2250KVA Cummins Diesel Generator. The old muffler had rusted and lost its effectiveness, so they approached the Flowtech team for help.

Our task was to design a modern silencer that would not only reduce noise but also resist corrosion and last longer.

January 4, 2024

No Comments

Custom

Custom Muffler For Railing Equipment

Once again, our loyal client in Western Sydney has entrusted the Flowtech team. The team designed a unique muffler that serves as a filter and a silencer effectively minimizes the emission of harmful fumes and reduces noise levels.

November 7, 2023

No Comments

Custom

Caterpillar Forklift Spark Arrestor Muffler

Our client, a Victoria-based company in Australia specializing in diesel generator and engine solutions faces a similar issue and now requires a customised muffler for their 110kVA Cummins Diesel Generator. The objective was to meet certain noise level reduction (35-40 dBA) requirements while enhancing safety by reducing the emission of hot particulates from engine and exhaust systems.

September 26, 2023

No Comments

Catalytic Converters

Fire Pump Exhaust Pipe System

Our client, a Victoria-based company in Australia specializing in diesel generator and engine solutions faces a similar issue and now requires a customised muffler for their 110kVA Cummins Diesel Generator. The objective was to meet certain noise level reduction (35-40 dBA) requirements while enhancing safety by reducing the emission of hot particulates from engine and exhaust systems.

August 23, 2023

No Comments

Custom

Custom DPF

The custom-designed muffler featured an innovative design which allowed it to be easily installed on the existing blower without having to make any major alterations. The muffler was designed to reduce the decibel level of the existing blower while still providing efficient airflow.

July 21, 2023

No Comments