Generator Heat Blanket

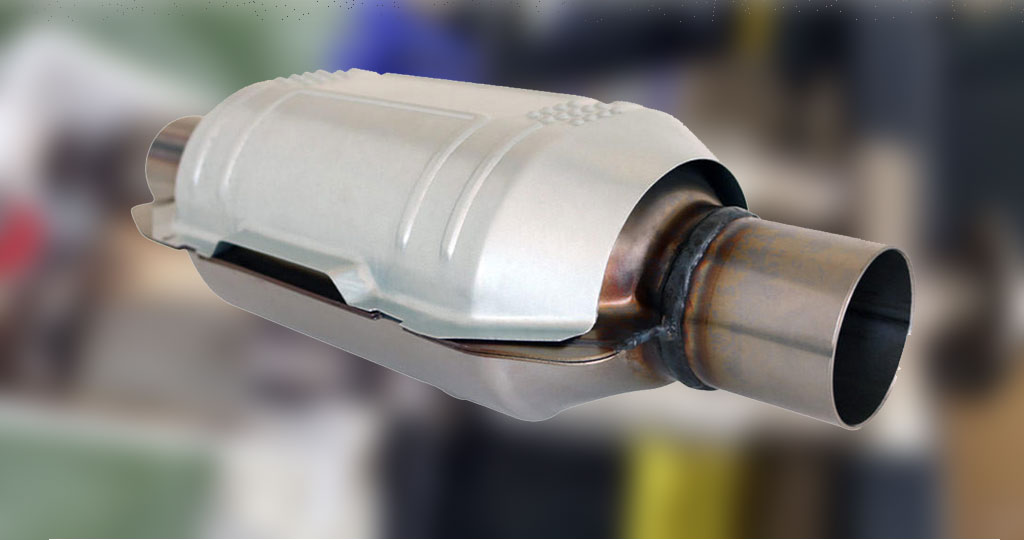

Our client operates within the sand mining sector, heavily relying on CAT generators for their daily functions. The objective was to replace deteriorating mufflers with Flowtech Silencers to curb emissions and reduce noise pollution. This improvement was crucial for adhering to updated environmental standards and enhancing the workplace atmosphere.