Frequently Asked Questions

Here are some of the most frequently asked questions about Spark Arrestors

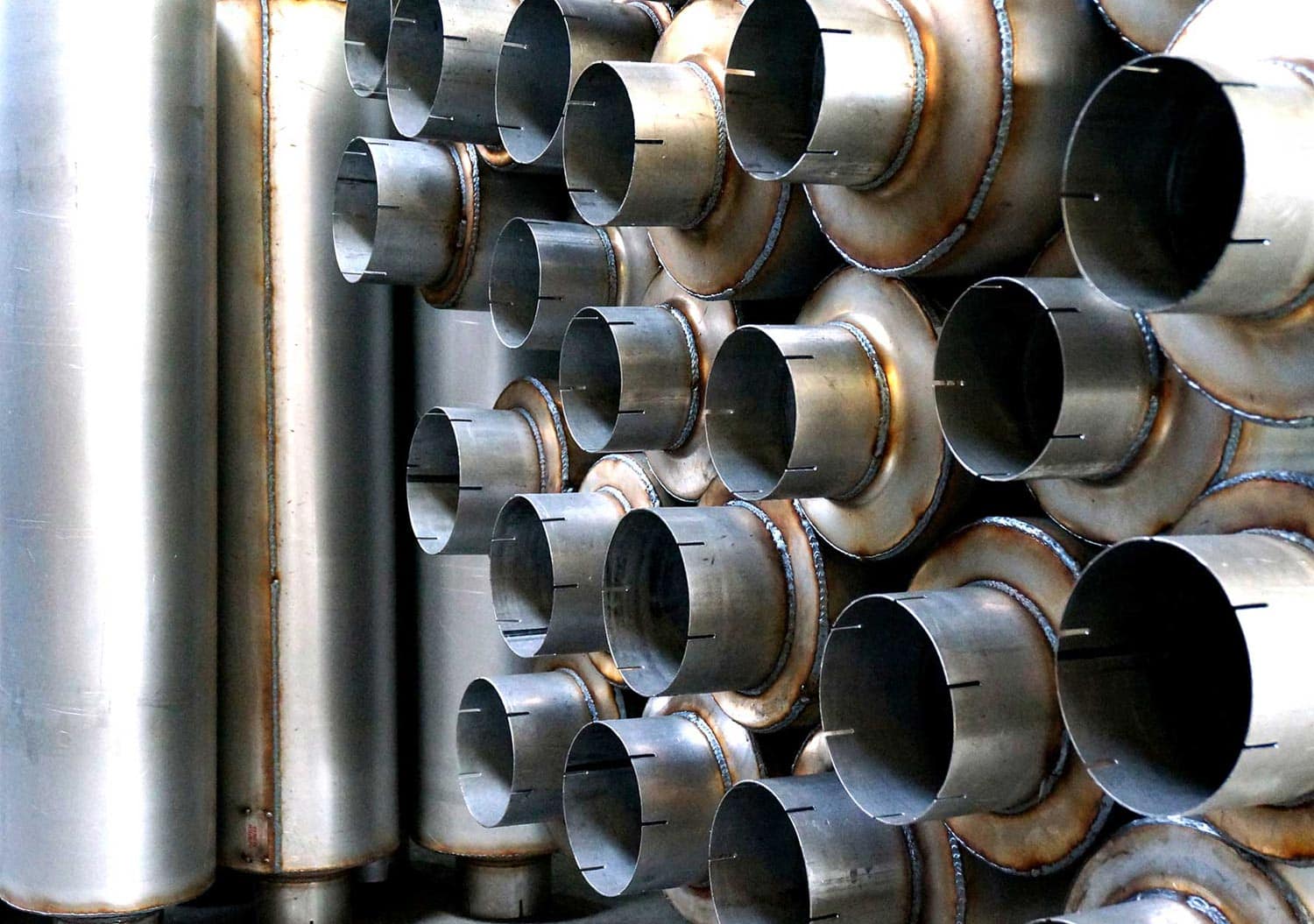

A spark arrestor (by Flowtech) is a component that is fitted to the exhaust system of a vehicle or engine to reduce the risk of fire. The primary purpose of a spark arrestor is to intercept and extinguish any sparks or embers that may be emitted from the exhaust system before they have a chance to ignite any flammable materials in the vicinity.

Spark arrestors by Flowtech work by catching the sparks before they have a chance to escape from the exhaust system. This prevents the sparks from igniting any flammable materials that may be near the exhaust system.

A spark arrestor works by creating a barrier that prevents sparks from exiting the exhaust system. One of the common types of spark arrestors is a special Screen-Type style that is made of S/Steel High-Temperature metal mesh. The other style has a specially designed Fan-Type inside to break up the sparks before they can escape.

Any engine that uses an internal combustion process needs a spark arrestor. This includes gasoline engines, diesel engines, and even some types of aircraft engines.

When choosing a spark arrestor, it is important to consider the following factors.

- Engine type example Petrol or Diesel?

- Horsepower of the engine?

- Is the engine Turbo or naturally aspirated?

- The O.D pipe size of the exhaust it is to be fitted onto?

- Does it need to comply with the Australian Standard AS1019-2000?

Once you have these details you can contact our friendly team to help you choose the correct Spark Arrestor.

If your exhaust system uses Diesel or Petrol fuel and is being used near anything flammable, like dry grass, fuel depots or mine sites then you really need to run a spark arrestor.

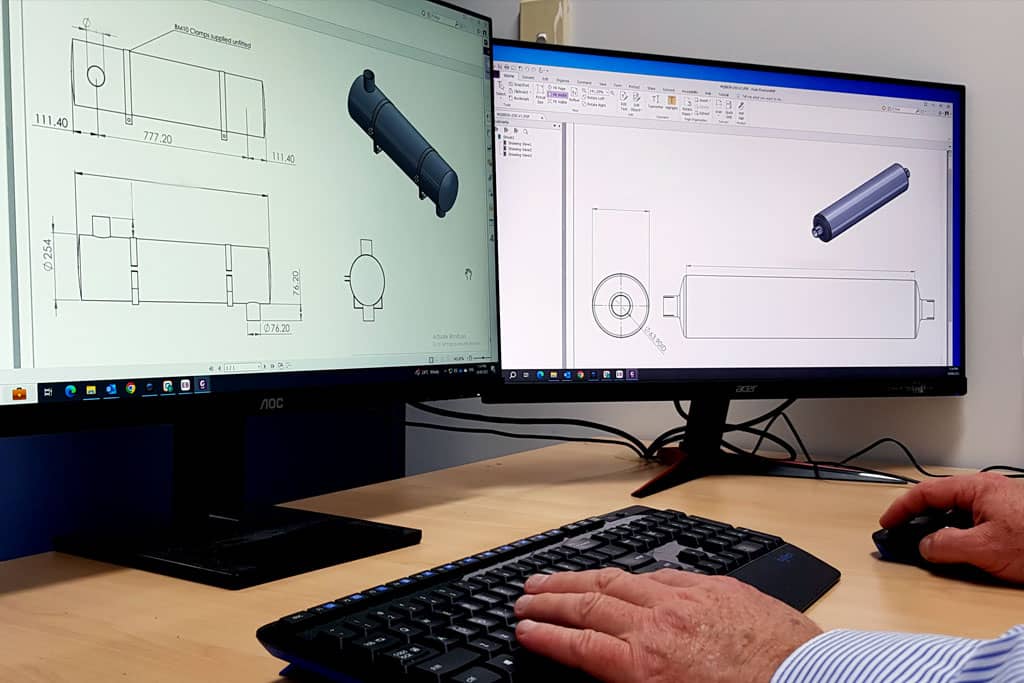

Installing a spark arrestor is typically a straightforward process. They are usually clamped on or can be welded on.

Maintaining your spark arrestor is simple. You should regularly inspect the device to ensure that it is free of debris and damage. Additionally, you should replace the device if it becomes damaged or worn out. To avoid any issues, have a qualified technician check and replace your spark arrestor.

If the spark arrestor is correctly designed and sized correctly then there will be no disadvantage. However, if the spark arrestor is not sized or designed correctly it can cause back pressure which can restrict the flow of exhaust gases and decrease engine performance.

While there are many suppliers of spark arrestors on the market, very few manufacturers produce Arrestors that comply with the Australian Standard AS1019-2000. Numerous prominent companies in Australia and New Zealand favour Flowtech Spark Arrestor as their top supplier because of its compliance with spark arrestors and extensive experience with emission control.

Fewer wildfires

One of the primary benefits of using a spark arrestor is that it can help to prevent wildfires. Spark arrestors are devices that are placed on the exhaust pipes of vehicles, engines, and other combustion sources. They work by trapping sparks and other hot embers that could potentially ignite a fire. In areas where wildfires are a risk, spark arrestors can help to reduce the number of fires that occur each year.

Reduced property damage

Spark arrestors can also help to reduce property damage caused by wildfires. When a wildfire occurs, it can destroy homes, businesses, and other structures in its path. By preventing wildfires from occurring in the first place, spark arrestors can help to protect property from damage.

Reduced deforestation

Deforestation is another side effect of wildfires that can be reduced by using spark arrestors. When a forest fire occurs, it not only destroys trees and other vegetation, but it also damages the soil. This can lead to erosion and landslides, which can further damage the environment. By preventing wildfires from occurring, spark arrestors can help to reduce deforestation and protect the environment.

Improved public safety

Using spark arrestors can also improve public safety by preventing fires from occurring in the first place. Wildfires can pose a serious threat to human life, as they can spread quickly and be difficult to control. By preventing fires from starting, spark arrestors can help to keep people safe from harm.

Reduce Cost

By fitting your vehicle with a spark arrestor, you may be eligible for reduced insurance rates from some companies. Before being insured for work in fire-danger areas, many insurers require that earthmoving equipment like trucks and tractors have an AS1019-2000 spark arrestor fitted.