Flowtech Catalyst Combination Filter

The Flowtech Catalyst Combination filter is meticulously engineered to effectively lower emissions to meet the standards required across various applications. This filter is popular for its

To provide a solution for eliminating toxic exhaust emissions. This includes toxic gasses such as Carbon Monoxide (CO) Hydrocarbons (HC), and Diesel Particulate Matter (DPM)

Carbon Monoxide

Carbon monoxide is an odourless, tasteless, and colourless gas that can be poisonous in large amounts. If you’re exposed to too much of it, you could lose consciousness and suffocate within minutes without any warning.

Hydrocarbons

Can penetrate deep into your respiratory system, producing inflammation, narrowing of the airway leading to deprivation of oxygen for every day bodily functions.

Diesel Particulate Matter

Can be so fine(less than 1-micron diameter) that it penetrates deep into the respiratory system which can lead to heart and lung damage.

The Flowtech Catalyst Combination filter is meticulously engineered to effectively lower emissions to meet the standards required across various applications. This filter is popular for its

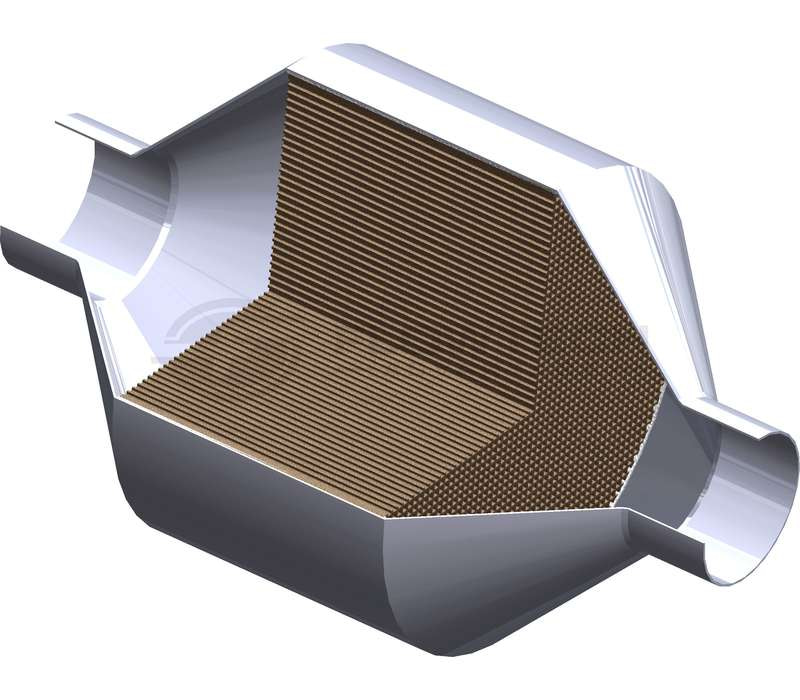

This Diesel Particulate Filter with Pre-Catalyst is a specialist combination designed to remove High levels of Carbon Monoxide (CO), Hydrocarbons (HC), and high levels of

Ceramic Diesel Particulate Filters are designed to remove High levels of Carbon Monoxide (CO), Hydrocarbons (HC), and High levels of Particulate Matter (PM) from Diesel

The Flowtech Diesel Oxidation Catalysts, or DOCs, can be a lifesaver when it comes to reducing emissions from diesel engines and equipment. Whether you’re driving

They provide reliable protection against fire hazards and meet the highest industry standards. With a wide range of models to choose from, we have the perfect solution for your specific needs.

The purpose of an exhaust emission control system is to reduce the pollutants that are emitted from a vehicle’s exhaust pipe. Catalytic converters, particulate filters, and oxygen sensors are all common components of an exhaust emission control system.

Catalytic converters use a catalyst to convert harmful pollutants into less harmful substances. Particulate filters remove tiny particles from the exhaust stream, and oxygen sensors help to optimize the air-to-fuel ratio in order to minimize emissions of nitrogen oxides (NOx).

There are several industries that need emission control, but the top three are the automotive industry, the manufacturing industry, and the energy industry.

The automotive industry is one of the largest sources of emissions around the globe. By implementing systems that reduce emissions from cars and trucks, we can help improve air quality and protect public health.

The manufacturing industry also contributes a significant number of emissions to our environment. By installing equipment that captures and recycles pollutants, we can reduce their impact on our planet.

And finally, the energy industry is responsible for a large percentage of greenhouse gas emissions. By investing in clean energy technologies, we can reduce our reliance on fossil fuels and help combat climate change.

Emission control for heavy duty vehicles is important because it helps to reduce the amount of pollutants that are released into the air. This is beneficial for both the environment and public health, as it helps to reduce smog and respiratory problems. Emission control systems also help to improve fuel efficiency, as they reduce emissions from the engine. This means that the vehicle can run more efficiently and use less fuel, which leads to reduced greenhouse gas emissions.

Diesel engines generate high levels of particulate matter (soot) and nitrogen oxides (NOx), both of which are harmful to human health. To comply with emission control regulations, heavy-duty diesel vehicles are equipped with a diesel particulate filter (DPF) and a selective catalytic reduction system (SCR).

Heavy duty vehicles present a unique challenge when it comes to emissions control. Their size and weight mean that they use more fuel, which in turn creates more emissions. In addition, many of these vehicles are used in transportation or construction, which can create additional air pollution.

Fortunately, there are several technologies that can be used to reduce emissions from heavy duty vehicles. These include:

– The use of Diesel Particulate Filters, or DPFs, is vital in maintaining a clean engine by trapping soot particles. When the filter becomes clogged, it doesn’t allow exhaust gases to escape as quickly as needed and can cause permanent damage to your engine.

-Efficient exhaust systems that capture and recycle fumes (see Flowtech solutions. Click here)

-Improved engine design and engineering

-Alternative fuels such as hydrogen or biodiesel

-Reduced friction in the engine using synthetic lubricants

There is no definitive answer to this question as each business is unique and will require a different type of emission control system. However, some tips on choosing the best system for your business include:

– See Flowtech actual emission control projects here

– Contact our emission control experts who can help you choose the best system for your needs.

Get in touch now 1300 885 089

Euro 4 and 5 emission control standards are the latest in emissions regulations for motor vehicles. They were introduced in Europe in 2005 and 2010, respectively.

Australia adopted Euro 4 emissions standards for new light vehicles in 2010, and Euro 5 emissions standards for new heavy vehicles in 2014. The aim of these standards is to reduce harmful exhaust emissions from motor vehicles, which can cause health problems for people exposed to them.

(Flowtech product related to Euro 4 & 5. Click here)

There are many types of emission control systems available for buses and trucks, but the most effective type is the catalytic converter. A catalytic converter uses a catalyst to convert harmful emissions into less harmful emissions. They are an important part of a vehicle’s emissions control system and help to keep our air clean.

(Flowtech product related. Click here)

Here are the top three reasons why we’re their preferred solution provider

Homegrown and proud, Innovating solutions for three generations, providing a wide range of customised exhaust systems that are robust, reliable and cost effective to meet the diverse demands of our clients.

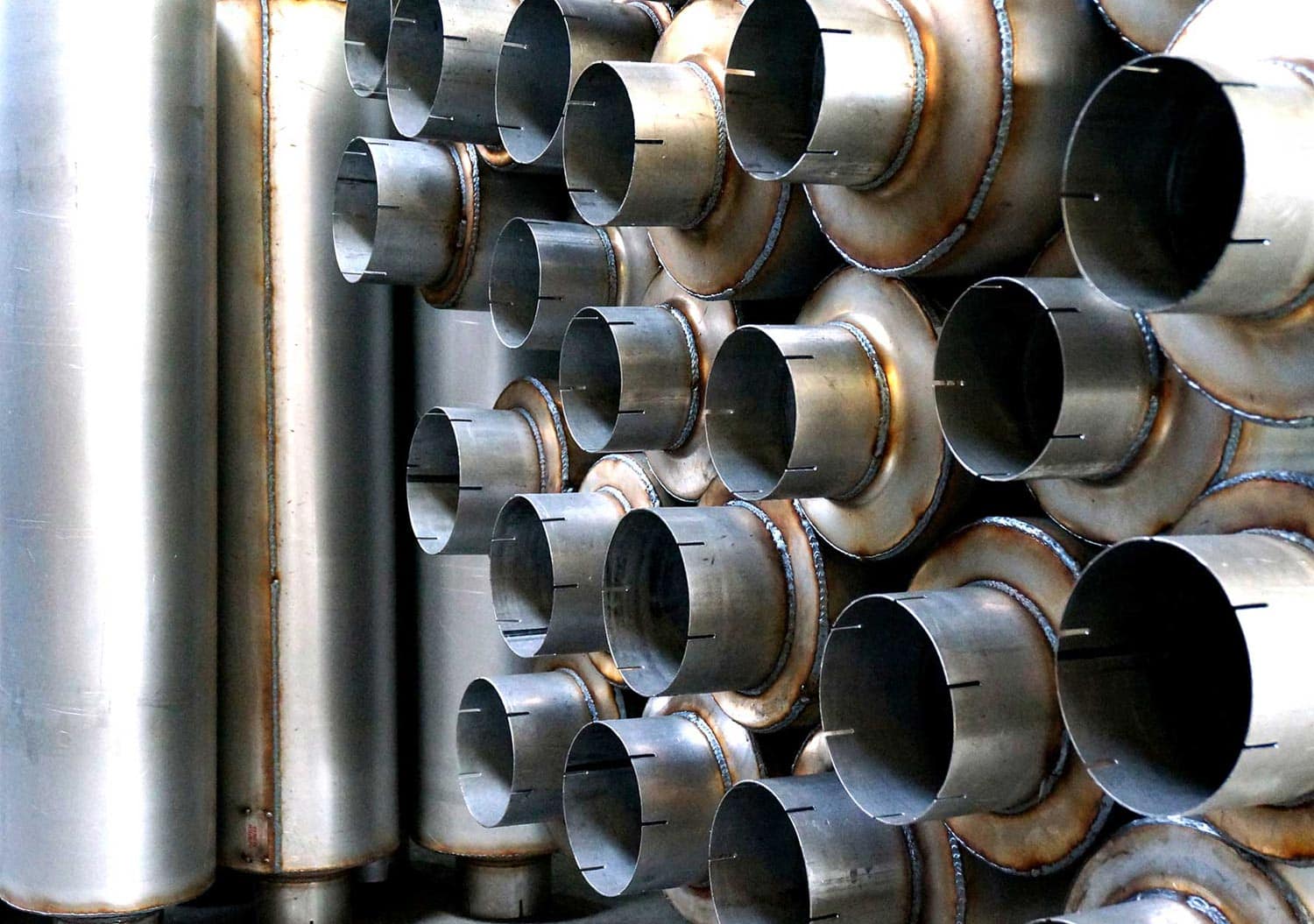

What sets us apart is our unique custom exhaust and emission control solutions with quick turnaround times that we can distribute throughout Australia & New Zealand.

We understand that when you place an order, you want it expedited as quickly as possible. That's why we offer same-day dispatch on all standard items. Your order will be processed and shipped out within 24-hours.

Top mining, automotive and multiple industries trusted our service for more than three decades. We Specialised in designing and manufacturing high-quality exhaust products that meet the unique needs of our clients.

Let us assist you in finding a reliable exhaust solution tailored to your needs.

Since 1984, Flowtech Advantage has been a key manufacturing division of CSC Group Australia. With its main headquarters in Western Sydney, the company designs and produces exhaust solution components for most industries in Australia and New Zealand.

Fill in your details and we’ll send you regular updates about Flowtech Advantage products.