Innovation in Emissions Treatment on CAT 120M Grader

When it comes to heavy machinery, finding an emission control solution is crucial.

In this case study, we see how the client’s requirement for an effective emissions control solution was achieved within the same casing area previously occupied by the original genuine silencer on a CAT 120M Motor Grader.

This innovation is a game-changer in terms of improving emission output yet creating the solution as a simple, direct-fit replacement unit.

The CAT 120M Motor Grader plays a key role for our client in construction and road maintenance projects with its powerful Cat C7 engine and heavy-duty capabilities.

In its current operational scope, a key focus is on aligning emission output with precise environmental standards without compromising performance, and without necessitating additional external equipment that could obstruct visibility or operations, or demand intricate maintenance on the grader.

SOLUTION

SOLUTION

ISSUE

ISSUE

The ideal process would be a unit in that mounted under the bonnet using the same mounts as the genuine silencer.

It was also a requirement to re-install heat blankets on the exhaust as per the existing. Determining that the Flowtech Diesel High-Flow Combination Filter met their desired emission outcomes, the client instructed the Flowtech team to develop the unit based on accurate dimensions provided by the client of the genuine silencer.

This ensured the grader could continue certain operations while the new part was being designed and built.

The Benefits of Flowtech's Filtration Technology

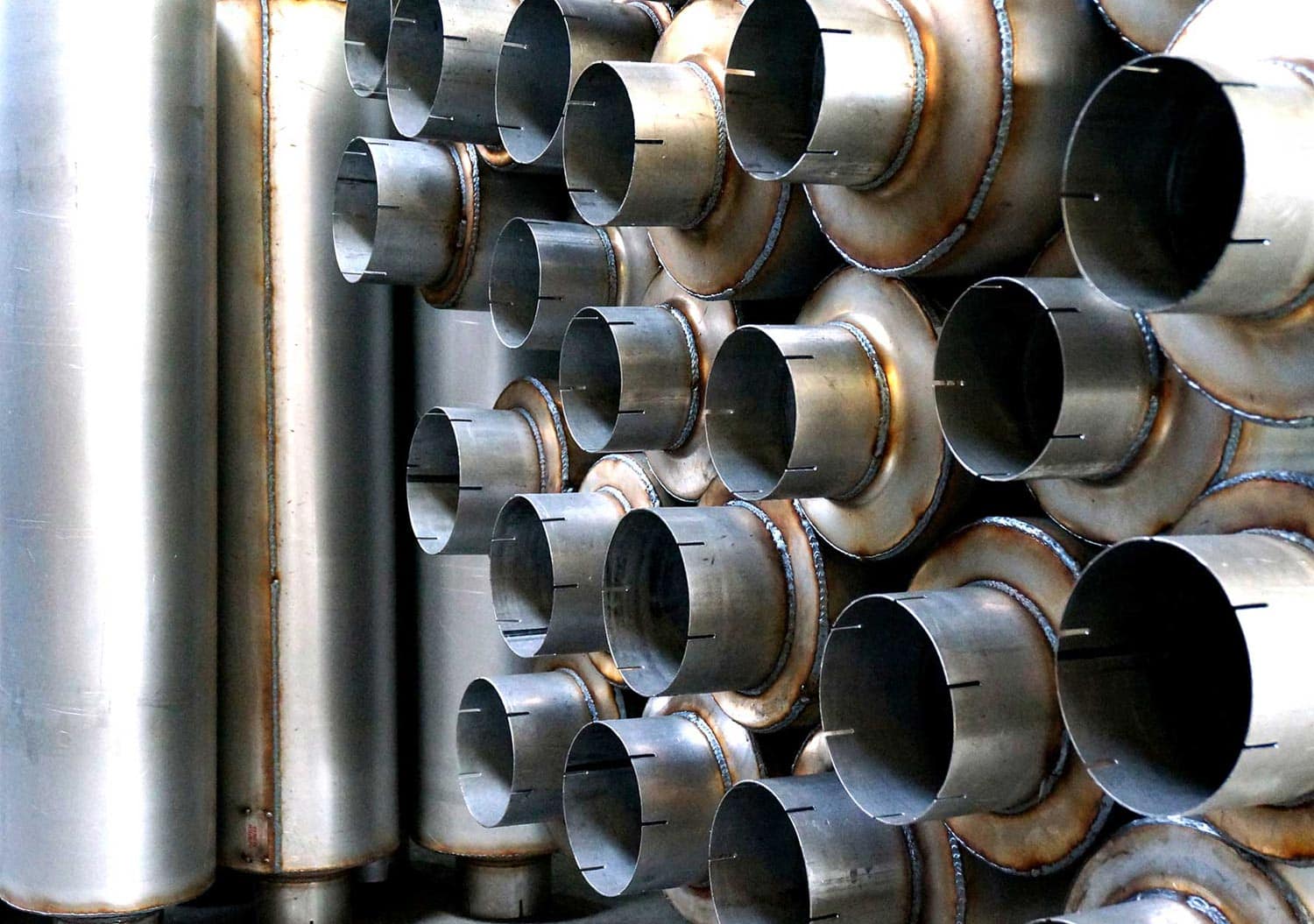

The Flowtech Diesel High-Flow Combination Filter has been proven to reduce harmful particulate emissions by up to 75%.

This is achieved with a combination of two advanced filtration technologies that work together to capture and remove particulate matter and other pollutants from the exhaust stream.

Additionally, this filter operates within typical backpressure limits for optimal engine performance, preventing any adverse engine performance or excessive fuel use.

Usually crafted from aluminized material or in certain applications stainless steel, this filter system showcases a user-friendly design and can seamlessly operate on the equipment.

Distinctly Australian-made, it has successfully completed all crucial phases encompassing research, production, testing, and delivery.

Custom-designed filter for the CAT140M Motor Grader

We also had the opportunity to design and supply a high-flow combination filter for the CAT140M Motor Grader for another client.

This filter has been specifically designed to meet the requirements of heavy-duty equipment used in the construction and mining industries.

Conclusion

The remarkable decrease in harmful emissions is not the only advantage offered by the Flowtech Diesel High-Flow Combination Filter. Its implementation also marks a significant milestone in heavy machinery operational cost savings.

By minimal impact on fuel efficiency and requiring less frequent maintenance, the operator of the CAT 120M Motor Grader will notice a marked improvement in operating emissions with barely a change in maintenance or performance.

Looking for a similar solution?

We have a wide range of muffler solutions for every industry.

Explore our Spark Arrestors, Exhaust Silencers, Emission Control, Aftemarket Exhaust Parts and Performance Muffler

This project is related to Generator Muffler Silencer

Products related to this project

Discover More Case Studies

Our exhaust solutions are custom tailored to suit your specific needs.

Silencers

Silencer designed for CAT 3412 Diesel Generator

Our client in Sydney needed a new muffler for their 2250KVA Cummins Diesel Generator. The old muffler had rusted and lost its effectiveness, so they approached the Flowtech team for help.

Our task was to design a modern silencer that would not only reduce noise but also resist corrosion and last longer.

January 4, 2024

No Comments

Custom

Custom Muffler For Railing Equipment

Once again, our loyal client in Western Sydney has entrusted the Flowtech team. The team designed a unique muffler that serves as a filter and a silencer effectively minimizes the emission of harmful fumes and reduces noise levels.

November 7, 2023

No Comments

Custom

Caterpillar Forklift Spark Arrestor Muffler

Our client, a Victoria-based company in Australia specializing in diesel generator and engine solutions faces a similar issue and now requires a customised muffler for their 110kVA Cummins Diesel Generator. The objective was to meet certain noise level reduction (35-40 dBA) requirements while enhancing safety by reducing the emission of hot particulates from engine and exhaust systems.

September 26, 2023

No Comments

Catalytic Converters

Fire Pump Exhaust Pipe System

Our client, a Victoria-based company in Australia specializing in diesel generator and engine solutions faces a similar issue and now requires a customised muffler for their 110kVA Cummins Diesel Generator. The objective was to meet certain noise level reduction (35-40 dBA) requirements while enhancing safety by reducing the emission of hot particulates from engine and exhaust systems.

August 23, 2023

No Comments

Custom

Cummins Diesel Generator Muffler

Our client, a Victoria-based company in Australia specializing in diesel generator and engine solutions faces a similar issue and now requires a customised muffler for their 110kVA Cummins Diesel Generator. The objective was to meet certain noise level reduction (35-40 dBA) requirements while enhancing safety by reducing the emission of hot particulates from engine and exhaust systems.

August 10, 2023

No Comments

Custom

Custom DPF

The custom-designed muffler featured an innovative design which allowed it to be easily installed on the existing blower without having to make any major alterations. The muffler was designed to reduce the decibel level of the existing blower while still providing efficient airflow.

July 21, 2023

No Comments